Add value. Eliminate waste.

“We are doomed to failure without a daily destruction of our various preconceptions.” – Taiichi Ohno, father of the Toyota Production System

Recently I’ve been eyeing the meadow that in theory is supposed to be my backyard, watching it mark its slow transition from winter slumber into something I need to mow, and not particularly looking forward to the prospect, so I thought a bit about why that was. I like being outside. Mowing isn’t particularly hard for me.

I thought about the process of mowing the lawn. I thought about getting the mower out of the shed, getting a battery from the charger and installing it, awkwardly maneuvering it down the rocky terrain to the backyard, realizing I didn’t pick up the branches from the enormous cherry tree in the yard, stopping to do that, then finally mowing the yard and reversing the process to put everything away.

If I think about it before I try to mow, it’s obviously wasteful to pick up sticks after I start, so it would probably make sense to do that before. And there doesn’t seem to be any value in wrestling the machine over rocks to get it to the place it needs to be used in. Maybe I could store it somewhere behind the house?

In Lean manufacturing, or the Toyota Production System, the concepts of value and waste are inherent and of special significance.

“The slower but consistent tortoise causes less waste and is more desirable than the speedy hare that races ahead and then stops occasionally to doze.” – Taiichi Ohno

Let’s explore a little more deeply into what I mean when I talk about value and waste.

In Lean, value-added activities are contingent upon three things being true:

- The step must change the form or function of the product or service

- The customer must be willing to pay for the change

- The step must be performed correctly the first time

I could summarize this as:

If it is transformative, desirable, and correct, it adds value. Anything else is waste and should be reduced or eliminated.

The ideas of adding value and eliminating waste are at least undercurrents throughout Lean philosophy. I’m sure I’m not the first to suggest that these concepts are transferable to other domains, such as your daily work, or even parenting.

Think about value and waste in your relationships – what things bring you closer and what things don’t? Wouldn’t it be nice to eliminate those things that don’t add value or improve your connection and focus on the things that do?

Think about the processes you follow to complete your daily work – are there any opportunities to reduce or eliminate steps that don’t enhance the value of what you are delivering?

In a relationship between any two people – parent and child, two partners, two colleagues, two friends – some wastes are relatively easy to identify, and others might take deeper introspection and retrospection to recognize.

Can you think of any wastes in your relationships?

I can.

Here’s one I recognized just the other day – if I say or do anything that in any way might threaten my wife’s confidence in cooking, or that even peripherally could be interpreted to question her ability to cook, it most certainly will not add anything of value to our relationship, and can only introduce defects. It fails the desirable check, and it arguably isn’t correct either. I decided to make conscious choices to support and reinforce her intrinsic value as a chef, rather than for example voicing any differing opinion I might have regarding what to add to a dish to make it better (lesson learned the hard way).

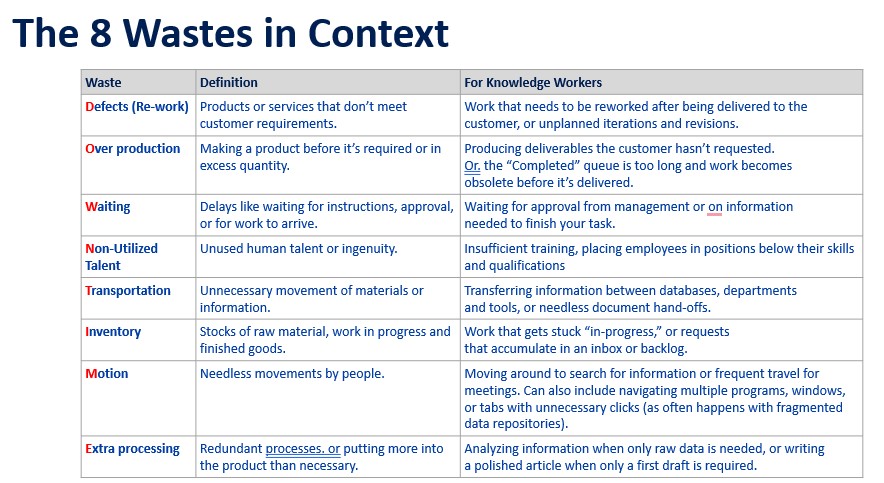

Having a preoccupation with eliminating or limiting waste, Ohno identified and described a set of basic lean wastes, which have been refined and expanded over time. Naturally they are oriented towards a manufacturing environment, but they can be placed within the context of other domains as well.

For example, here’s a chart of the eight Lean wastes and their context for knowledge workers (office workers, software developers and testers, etc.):

(I’m working on a “For Parents” column and will add it here when it’s ready.)

Scanning the table, you may already be able to relate some of these wastes to your own situations. Looking at “Defects“, I can imagine a product or service that doesn’t meet customer requirements being a meal I made for, but which was not appreciated by, my son. How to eliminate that waste? Maybe I’d involve him more in the meal planning and preparation process so that he has more of a stake in the meals.

Because I suppose it’s now tradition, and just to make it official, here’s the card:

No details to expand on… it is what it is.

Viewed through this lens, my lawn mowing process can be improved by addressing the waste of Non-Utilized Talent (my son)… comparatively I am a bit over-qualified for the position of lawn mower, and since it’s an opportunity for my son to learn and improve a work ethic, it actually adds value to him and to our relationship.

What wastes can you find in your processes or relationships?

Discover more from sharing perspectives

Subscribe to get the latest posts sent to your email.

Trackbacks & Pingbacks